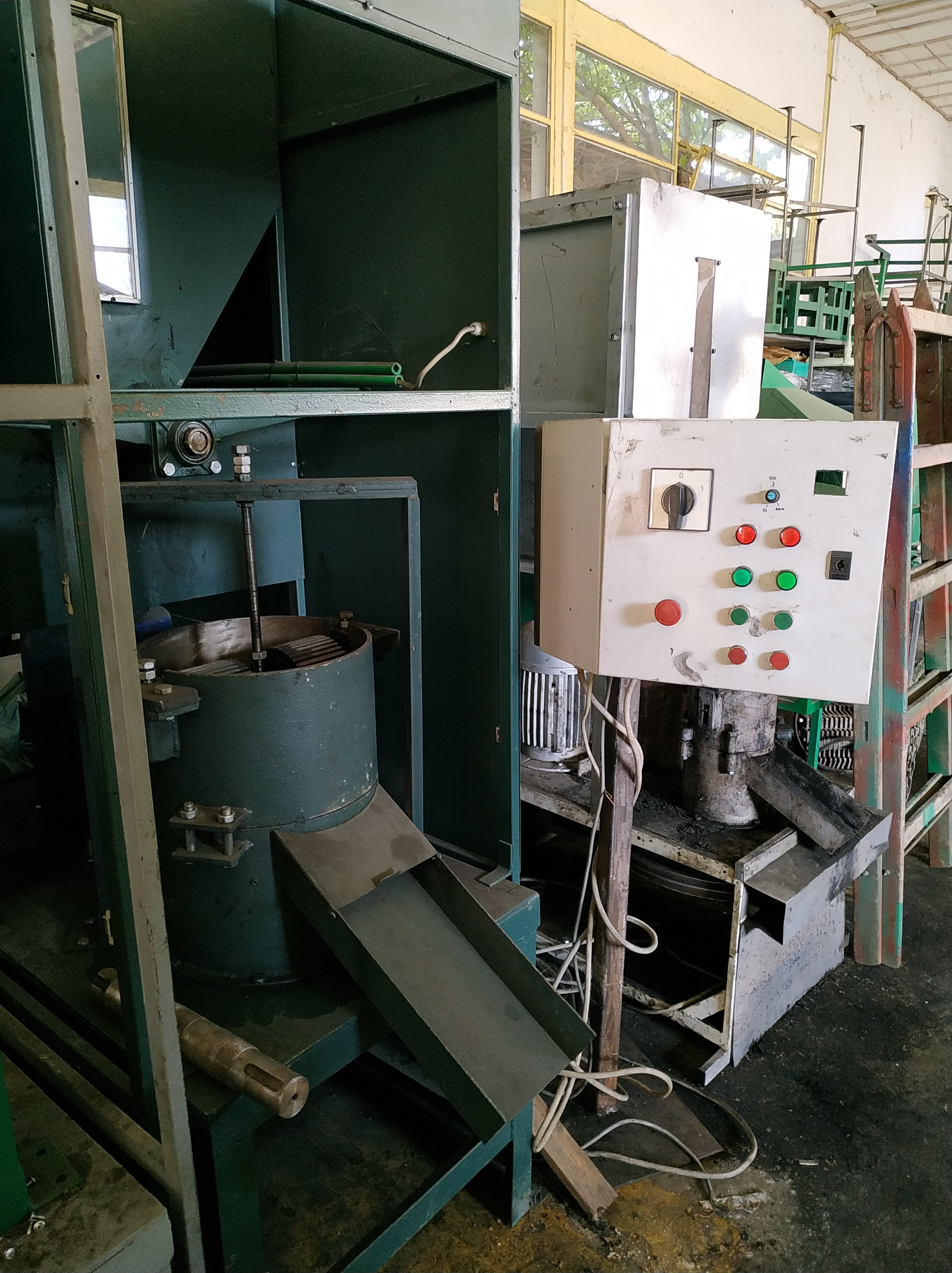

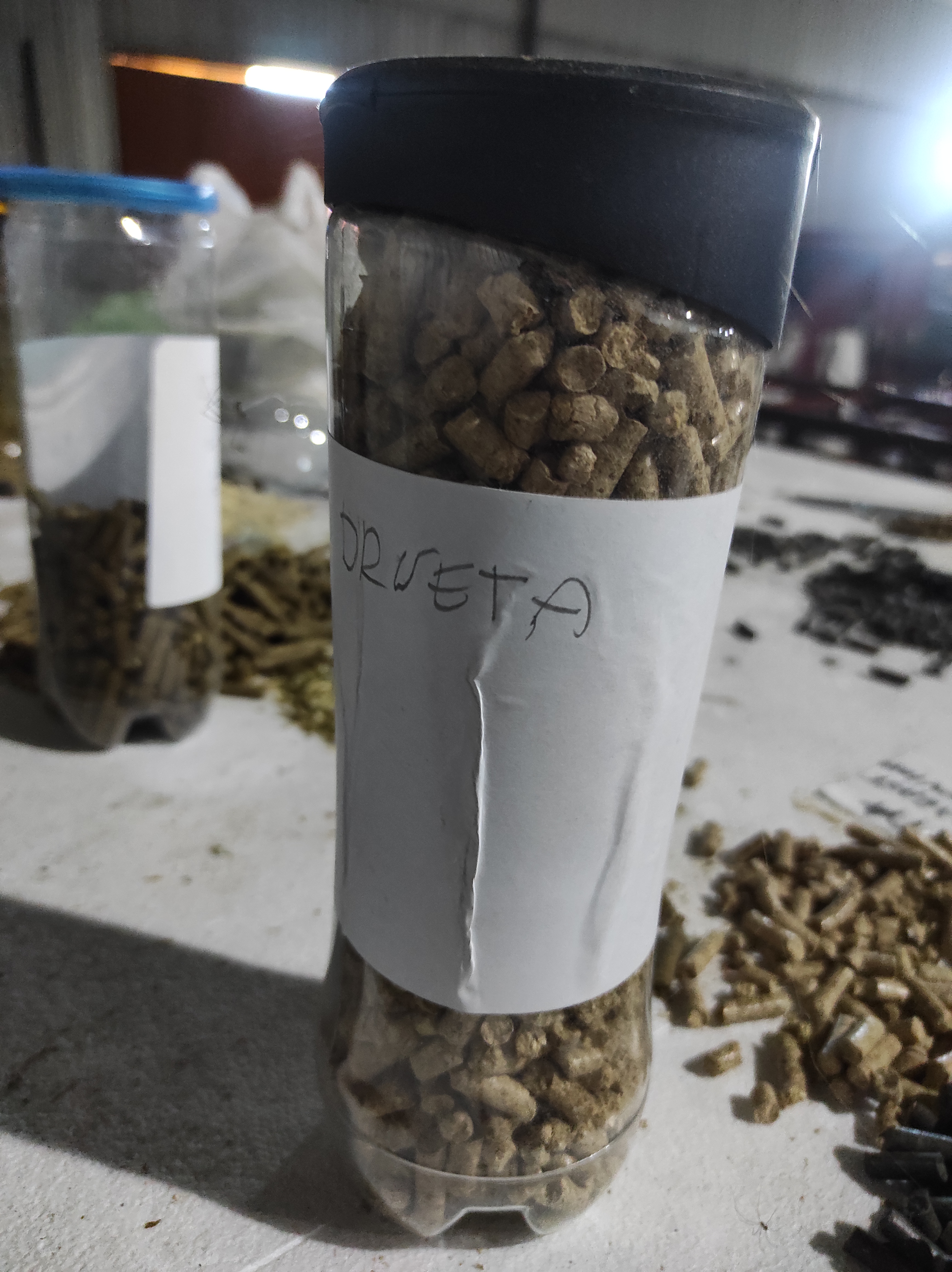

Briquette Plus offers pellet production machines with a production capacity of one to five tons of pellets per hour. Our machines are capable of producing compact pellets from various raw materials without the addition of any binding agents or additives, except for water. Some of the raw materials that can be converted into pellets using our machines include wood (sawdust), coal, coal dust, a mixture of coal and sawdust, animal feed, various types of manure, paper, zeolite, rubber, and plant biomass (such as sunflower residues, straw, sugar beet pulp, olive pits, alfalfa, and so on). The electricity consumption for a pellet machine with a production capacity of one ton per hour is only 47 kWh.

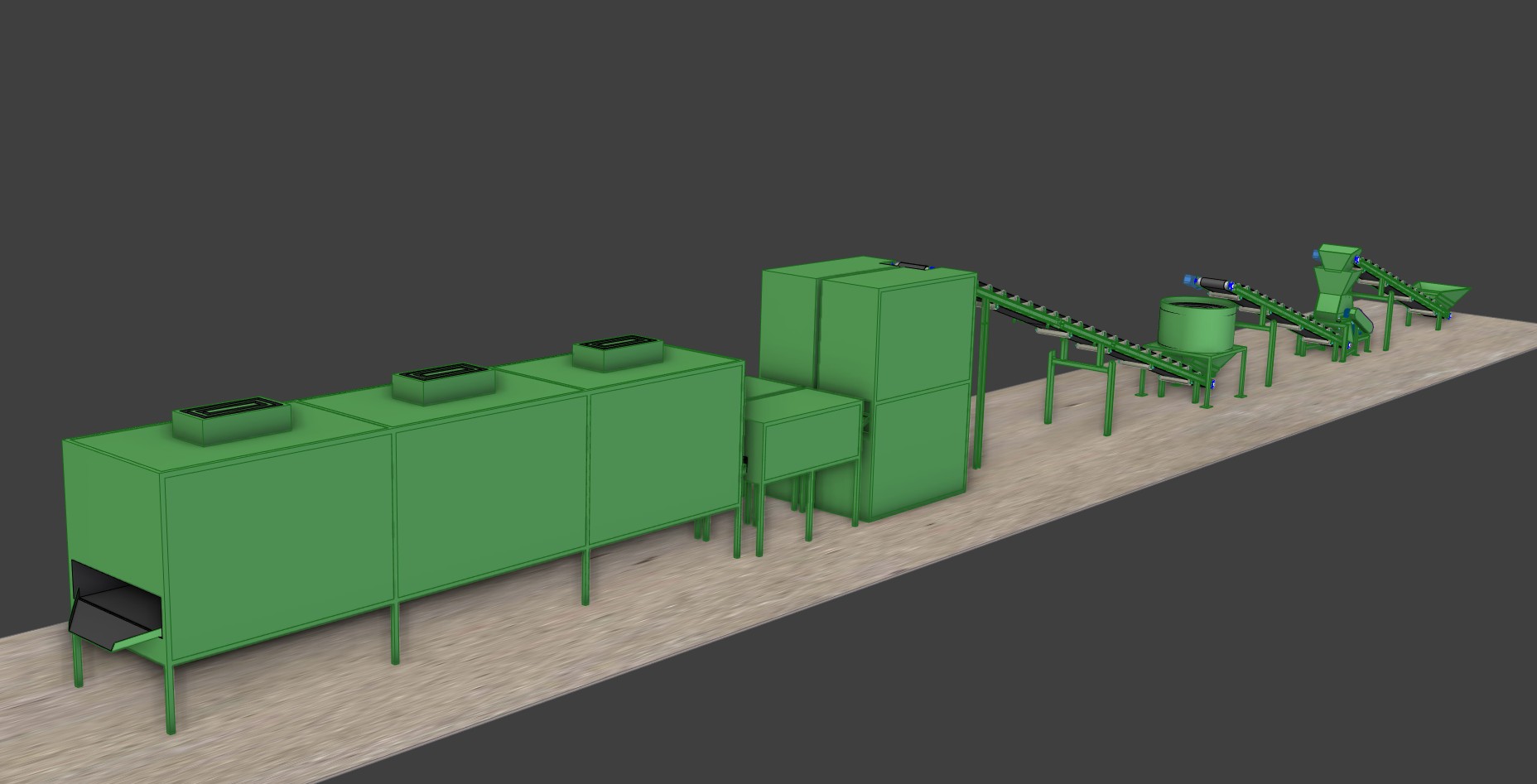

List of Pellet Machine Parts (Production Capacity 1 Ton Per Hour)

| Conveyor I | 0.37 kWh |

| Mill | 7.5 kWh |

| Conveyor II | 0.37 kWh |

| Mixer | 1.6 kWh |

| Conveyor III | 0.75 kWh |

| Two pellet presses (2 x 500 kg/h of pellets) | (2 x 11 kWh + 2 x 0,37 kWh) |

| Continuous Conveyor Dryer + Sorting line | 11,5 kWh + 2 × 0,5 kWh + 2 x 0,37 kWh) |

| Total electricity consumption of pellet machine with production capacity of 1 ton of pellets per hour | 46.57 kWh |

Our pellet machines are characterized by:

» Lower monthly maintenance costs and lower spare parts prices compared to other machines on the market (our company provides regular monthly servicing of machines in agreement with customers)

» Low electricity consumption of only 46 KWh, which positively impacts business profitability

» High production capacity (1 to 5 tons of pellets per hour)

» Innovative and modern technology that ensures no harmful binding agents are added to the raw material during pellet production.

In addition to the pelletizing machine, we also manufacture a conveyor dryer with a conveyor belt and heaters, which is used as the final step in the pellet production process to reduce the moisture content in the final product. The total length of the pelletizing machine combined with the attached dryer is 26 meters, and its most important component is undoubtedly the pellet press, which transforms the milled material from the machine’s grinder into compact pellets.

CONTACT US

BRIQUETTE PLUS (BRIKET PLUS DOO KOVIN), company registration number (MB): 21109738

Machines for the production of briquettes and pellets

Trg Oslobođenja bb, Kovin, Serbia

All rights reserved (2025).